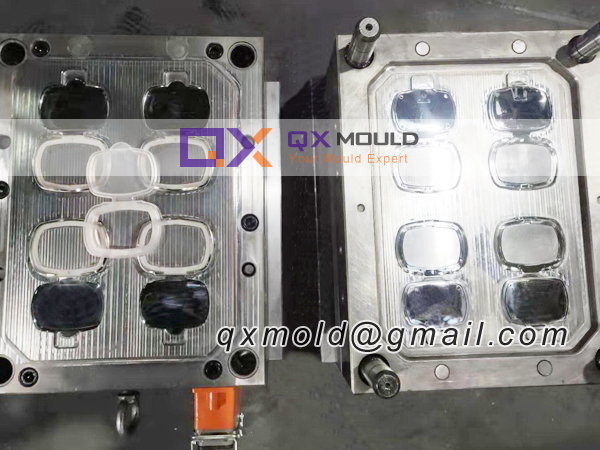

QX Mould is skilled in manufacturing plastic cap mold. We make flip top cap mold, shampoo cap mold, oil cap mould, cosmetic cap mould, anti-theft cap mould, thread cap mould, double color flip top cap mould, 5 gallon double color cap mould etc.

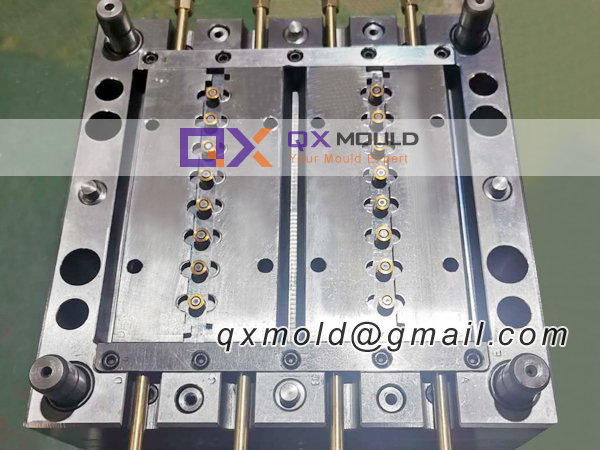

For making best quality plastic cap mold, we request hard mould steel and high grade mold standard component. Usually S136, 2316, H13 are widely used for producing cap mold. Becasue in order to achieve 48-52HRC hardness, mould steel need vacuum hardening and quenching treatment. Lots of cap moulds need hot runner system. We always use best quality hot runner. We also cooperate with YUDO etc these famous hot runner brand as per client requirement. Our China-made hot runner system are also popular for most clients.

When firstly seeing cap sample or cap drawing, our engineer immediately know which ejector system available for that cap mould. For making cap mould, stripping plate ejector and unscrewing ejector are normal ejector system and applicatable to almost plastic cap moulds. Most flip top cap mould(shampoo cap mould, lotion cap mould,etc), pharmaceutical cap mould, cosmetic cap mould(tube cap mould,etc) all these need unscrewing ejector system.

QX Mould have very rich experience of making unscrew ejector cap moulds. There are two designs of unscrewing ejector,hydraulic cylinder unscrewing and hydraulic motor unscrewing. Both these two designs are applied alot in our cap mould producing.