Mould parts processing and precision control

The stand of mold parts processing is closely related to product quality. QX Mould can handle mold parts, we have a professional quality control department to do the mold parts and products quality inspection. High level of machining accuracy is not just by simple skilled operation, this contains a lot of technology skills. That is to say, the high precision machine tool may not work out high precision products, because it lacks process technology; Low precision machine tool is also able to work out high precision product, because it has mastered the technology. So, to improve the machining precision of the CNC machine tools, the key is to improve the level of processing technology and enforced.

Factors hindering the machining accuracy of mould

1, the precision of the parts;

2, mould processing technology level; The technology level of mold assembly fitter;

3, the mode of production and management level.

Widely use hot runner

The so-called hot runner is used in injection mold, plastic will melt into the mold cavity of the heating components in the set. Hot runner system is divided into insulated runner and miniature half hot runner system. insulated runner is complex, but the effect is good and very low maintenance costs. Mini half hot runner structural simplicity, stable, low failure rate, low maintenance cost, to have more guarantee on the stability of the production.

The benefits of the hot runner of injection mold:

1, reduce the cycle time

2, save the plastic raw materials

3, reduce waste, improve the quality of products

4, to eliminate the follow-up process, be helpful for production automation

5, expanding the scope of the injection molding process application

Processing equipment

Injection mold is a kind of complex structure high precision mould, is currently the most widely used plastic mould, QX Mould processing equipment include lathe machine, milling machine, drilling machine, grinding machine, machining centers, EDM machine, line cutting machine, sawing machine, internal and external circular grinding machine, laser marking machine, boring machine, etc

Mould Test elements

QX Mould pay attention to smooth of mould open and close, inject smoothly. Second, pay attention mold gate location, inject way, gate size and the cavity size, to choose the appropriate injection pressure, speed, feed rate.We will check carefully whether the mould all cooperate in quality phenomenon, then confirm the parting line and exhaust. quality person will check the product appearance and size.

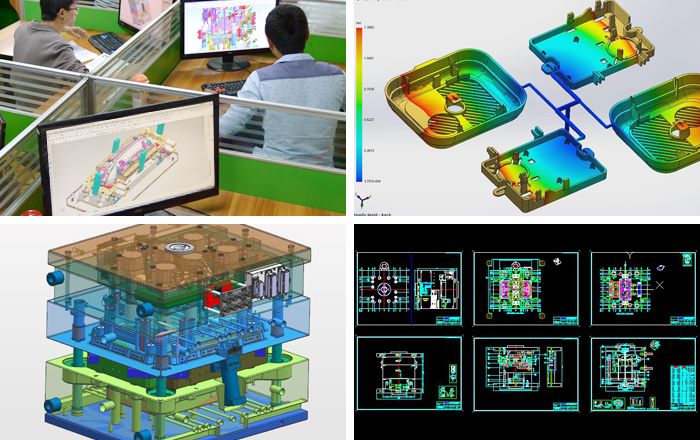

Mold Design

We can provide 3D or 2D drawings of products and molds.

- 2D drawings possible formats DWG, DXF.

- 3D drawings possible formats STEP, X-T, IGES.

- CAD / CAM Designs

Mold Manufacturing

Using high-precision numerical control CNC equipment.

- Numerical control CNC milling machines

- High speed numerical control engraving machine

- EDM, Grinding Machine, Drilling Machine etc.

Pre-sales and after-sales service

We provide detailed pre-sales service and after-sales service.

- Pre-sales service

- provide detailed production progress

- Provide high-quality after-sales service

-

1

Your idea or drawings.

We accept your idea in sketch, 2D drawings, various 3D formats, samples, etc.

-

2

Engineering and design

We analyze product drawings and provide corresponding mold design.

-

3

Mould production

During the production stage, we will send you regular updates of process status and process photos.

-

4

Trial and adjustments

After the mold installation is completed, mold trial, and send you samples, if there is any problem, it will be adjusted.

-

5

Shipment

When the right result will be reached, mold will be shipped. and provide after-sales service.